Towards computer vision feedback for enhanced CNC machining

Por um escritor misterioso

Last updated 22 dezembro 2024

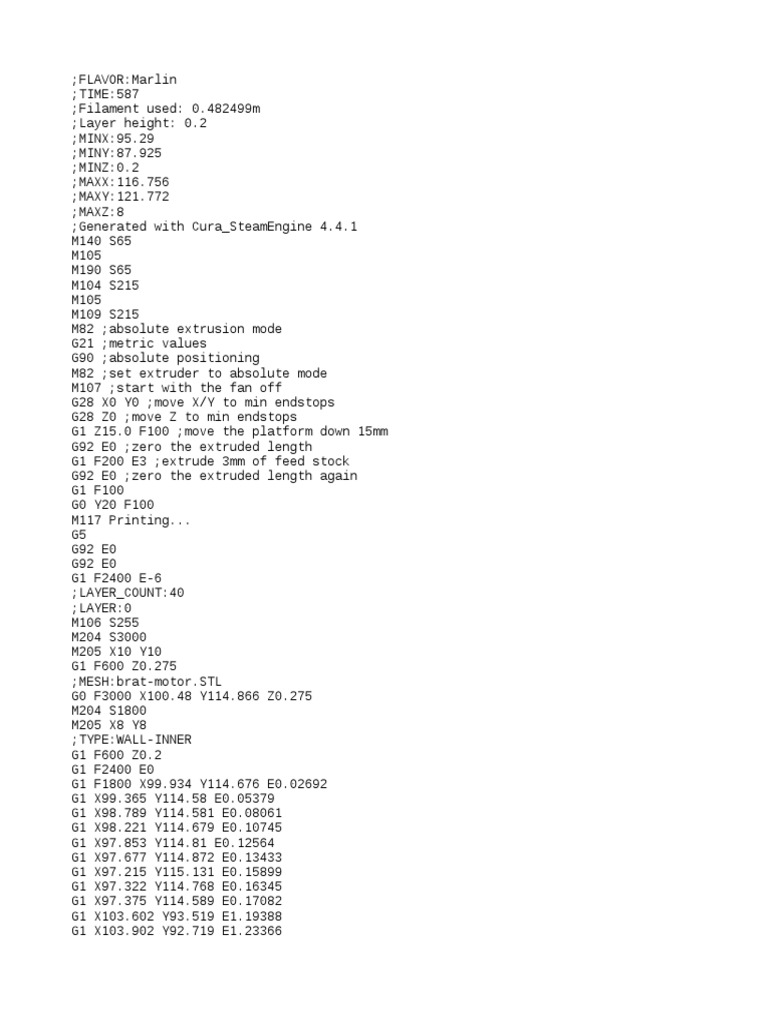

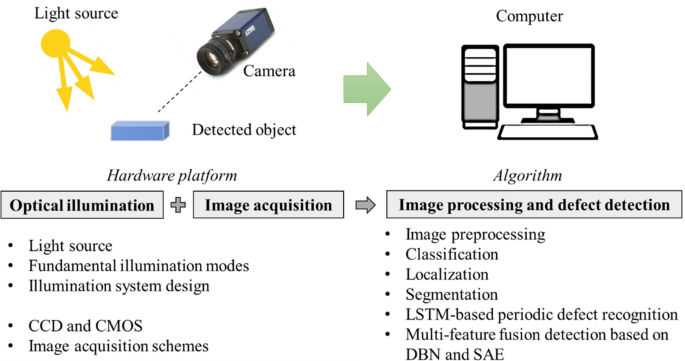

A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines and to facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file to enable real time integration of the gained feedback information. A vision-based sensing utility is proposed and developed to enhance the performance of CNC milling machines. Two cameras are attached to the machine spindle to provide visual information on work-piece surface quality while machining. This information is processed and processing outcome is used to improve the surface roughness of the machined part by adjusting the employed machining parameters. To facilitate on-line monitoring and control, computer programs are developed to manipulate the source G-code file in order to enable real time integration of the gained feedback information. The manipulated G-code program is then executed by the machine controller to allow adaptive control of the work-piece machining. The developed system automatically determines which camera is required to provide scene data for each step of tool path movement. Relative camera is then activated just as the machine completes the cutting of each tool path segment. Acquired vision data is processed to evaluate resulting surface roughness and accordingly a decision is made to either maintain the implied machining parameters or adjust their values to beneficially suit the machining task and result in better surface quality. The developed approach is tested and verified experimentally. Promising results are acquired that encourage further development towards full integration of CNC-vision systems.

Interest in Robotic Automation for CNC Machine Shops Increasing

Machine Vision Systems Capabilities, Uses, And Applications

What Is Machine Vision? – Metrology and Quality News - Online Magazine

Towards computer vision feedback for enhanced CNC machining

Vision Sensors in Factory Automation - Tech Briefs

What is next for 5-axis CNC technology?

Towards computer vision feedback for enhanced CNC machining

Arc1Cnc

How is 3D Machine Vision helping to Transform the Manufacturing

5-Axis Machining Guide Okuma CNC Machine Tools

State of the Art in Defect Detection Based on Machine Vision

Recomendado para você

-

1967 ford f100 custom interior22 dezembro 2024

1967 ford f100 custom interior22 dezembro 2024 -

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z22 dezembro 2024

New US Keyboard for HP Pavilion 17t-f100 17t-f100 17z22 dezembro 2024 -

Porsche Guards Red, 80K / 84A / M3A / G1 / G822 dezembro 2024

Porsche Guards Red, 80K / 84A / M3A / G1 / G822 dezembro 2024 -

Texoma F100 Round up Collection of Trucks and Bronco's22 dezembro 2024

Texoma F100 Round up Collection of Trucks and Bronco's22 dezembro 2024 -

About - Hudlow Axle22 dezembro 2024

About - Hudlow Axle22 dezembro 2024 -

AI3M Brat-Motor22 dezembro 2024

-

Interruptor Luz Freio F1000 F4000 Belina G1 G2 Corcel G1 G2 Del22 dezembro 2024

Interruptor Luz Freio F1000 F4000 Belina G1 G2 Corcel G1 G2 Del22 dezembro 2024 -

ODG - Painel de instrumentos Ford F100 Trapezoidal22 dezembro 2024

ODG - Painel de instrumentos Ford F100 Trapezoidal22 dezembro 2024 -

REL Acoustics G1 MKII Subwoofer Reviewed - Future Audiophile Magazine22 dezembro 2024

REL Acoustics G1 MKII Subwoofer Reviewed - Future Audiophile Magazine22 dezembro 2024 -

Camiseta Ford F100-V8 Feminina Preta22 dezembro 2024

Camiseta Ford F100-V8 Feminina Preta22 dezembro 2024

você pode gostar

-

Charadas: O que é o que é APK for Android Download22 dezembro 2024

Charadas: O que é o que é APK for Android Download22 dezembro 2024 -

Mavin Pokemon VMax Dragons Premium Collection - New In Box22 dezembro 2024

Mavin Pokemon VMax Dragons Premium Collection - New In Box22 dezembro 2024 -

Prefeitura Municipal de Lençóis Paulista22 dezembro 2024

Prefeitura Municipal de Lençóis Paulista22 dezembro 2024 -

JOGO P/ XBOX 360 CALL OF DUTY 4 MODERN WARFARE, DCM INFO22 dezembro 2024

JOGO P/ XBOX 360 CALL OF DUTY 4 MODERN WARFARE, DCM INFO22 dezembro 2024 -

Keystone Black Hills & Badlands - South Dakota22 dezembro 2024

Keystone Black Hills & Badlands - South Dakota22 dezembro 2024 -

N/A - Eu: Google me conte uma piada *Google: como acaba um jogo de futebol entre patos? Empatados Google / eu: - iFunny Brazil22 dezembro 2024

N/A - Eu: Google me conte uma piada *Google: como acaba um jogo de futebol entre patos? Empatados Google / eu: - iFunny Brazil22 dezembro 2024 -

Fortnite confirma crossover de Jujutsu Kaisen22 dezembro 2024

Fortnite confirma crossover de Jujutsu Kaisen22 dezembro 2024 -

Need for Speed II: Special Edition A Force for Good : classic PC gaming22 dezembro 2024

Need for Speed II: Special Edition A Force for Good : classic PC gaming22 dezembro 2024 -

Image tagged in memes,funny,my dog stepped on a bee - Imgflip22 dezembro 2024

Image tagged in memes,funny,my dog stepped on a bee - Imgflip22 dezembro 2024 -

Comfort Food Gumball Machine22 dezembro 2024

Comfort Food Gumball Machine22 dezembro 2024